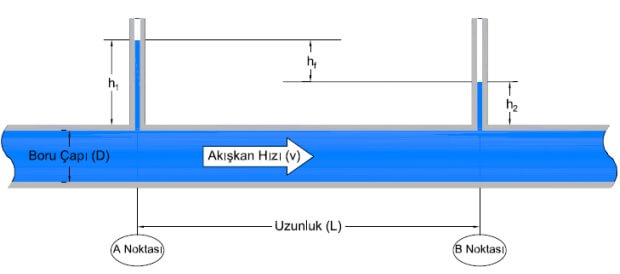

Arm Import from the main pipe steep (90 °) or 45 ° angles are done with pipes prepared. The main pipeline in the piping, the different points (the usage) fluid to be distributed (liquid-gas) must be made for the same or different diameters of pipe connections.

Handle Getting lottery in Black Pipe

Welding holds a unique place in the process of arm Import from pipes. Source provides many conveniences in making arms. Thin-walled pipes is provided to save time in case boiled with oxy-gas supply. combine preparation of the pipe section before welding must be made in full. welding techniques used in the assembly of pipes, and transportation of fuels such as oil and gas has become more important with pipes.

Fuel supply of materials or require the transfer of skills and knowledge that other fluid pipes. Pipe welding should be completed rapidly made possible. Done quickly record-high cash income from their small pipe thickness.

Boil the diameter of the pipes R = 2 “pipes up to direct R = 2” is boiled in a large opening with pipe weld. Especially small pipe in the registration nag-carbide is used very little flame. This provides a minimum width of melting. This should be 1 to 2 mm in width. Boiling method is more useful as a source of implementation left.

Convenience is one of the collection as soon as the flame heats up the melting area. With this source of stem technique (first) and the second consecutive easily pulled stitches. Thick-walled pipe are usually narrow angled weld opens. values of these angles of 50 ° – 80 °. The weld seam of the opening parts of the processing is better. The seam weld quality by increasing the space-niksel strength, approached the welded materials. The move away from the melt strength of the field oxide which is a factor in the increase of resources is done with additional wire. Pipes horizontal (flat) position if the subject starts from the source to the highest point. This is not possible, pipes must be rotated to the source location. Boiling point of the radius must be such that it is tangent.

The rotation of the pipe welding is not possible, ¼ of the pipe circumference ‘u-cup from NOK made up the top downwards. The melt zone during welding should be kept as small as possible. Pipes flat side (wall) and is welded at three locations, including the ceiling. The source of the pipe, combined with supply side is easily made. Oxyfuel welding is the most common type used in pipe welding bonding. four source location is applied in the circumferential welding of a pipe.

There are three important factors at the origin of a pipe:

1. Pipe thickness

2. Boiling location

3. accustomed to the joints of the pipe and returned to

Welding of the pipe line wire tangent 30 ° position, the angle of the nozzle opening of the wire is approximately 100 °.

Search section welding in pipe joining holds a very important place. These resources, edge to edge, boiled in three ways, including edge surface and substrate surface. Intersections studies used-trucks are usually implemented cutting with oxygen.

45º Arm Import

45º angle between the lever arm to get the main line to be taken with the main pipeline 45º d. handle diameter can be different as will also be outlined. In either case it must first be run in the tubes. Then drilled into the main pipeline and parts puntalan. It may need to be secured with mechanical devices for the lack of change in the position of parts.

90ºArm Import

90º angle between the lever arm to get the main line to be taken with the main line pipe 90º. As also outlined sleeve diameter can be different as will be the same as 45 °. In both cases, the lapping of the pipe is a priority. It is utilized to set the miter. Then drilled into the main pipeline and parts puntalan. For the lack of change in the position of parts mechanics need to be fixed to the instrument.

Arm Import from the elbow

In 90º and a coke to take 45ºdış the pipe is possible to encounter different applications. For example, shaped trousers (main end point in the same column from the left and right and up and down link) arms acquisitions are made. There elbow resources in changing direction. The encounter some cases elbows and pipe diameter can be different. As with the other arm making process must be accustomed to each other all the pipes encounter.