Vapor diffusion between the relative humidity of the transfer of the right amount of high volume to low volume loving-surface molecule composed of the inner and outer environment, resulting from the different temperature and relative humidity different vapor occurs pressures. Considering the winter the heating period generally has a high vapor pressure because of heat on the inside and water vapor which is in the internal environment of gas, acting in the same direction as the heat flow strives to reach the external environment. However, the vapor of a surface (ie channel surface) may occur if conditions become unfavorable water. Returning to a liquid gaseous water vapor, the channel forming material in the vapor and their resistance to heat transfer and the material is dependent on the order. Taking the necessary precautions by examining different methods for insulating become liquid water vapor should be provided.

Regarding the required vapor diffusion Concepts

Water vapor in the air

forming the atmospheric air is composed of different gases and water vapor mixture in a given ratio.Can be maintained in the gas increases as the air temperature increases, the amount of water vapor. When called saturation state is reached, the amount of water vapor in the air starts to wet the surface and appears in the contact becomes.

Relative humidity

The amount of water the air is carried as a percentage rate compared to its saturation. In other words, the relative humidity, the more water vapor weight of the water vapor in the air can hold at the same temperature of the air can be expressed as the ratio of the weight. The relative humidity of air, with the ratio of the partial water vapor pressure of saturated water vapor pressure at the same temperature can be represented. Relative humidity φ indicated by the letter and unitless.

φ = Available Water Vapor Amount / Amount of water vapor saturated state

φ = Available Water Vapor Pressure / State & the saturated water vapor pressure

In some applications, relative humidity, relative (relative) named the moisture percentage (%) also expressed. Relative humidity is the most important factor affecting the sweating temperature.

Dew point temperature

The dew point temperature of the air in certain circumstances, in the same circumstances and may call in the same amount as the temperature saturated air containing water vapor.

Inside the temperature of the surface in contact with air containing water vapor, deposition on the surface when water droplets fall below the dew point temperature that starts sweating. Surface temperature at the time of contact with the air temperature falls below a relative humidity of 100% in the form of sweating.

Water Vapor Diffusion Resistance Floors

Water vapor, depending on the temperature and relative humidity, the partial vapor pressure will move toward the low to high and proceeds also encounters a resistance. Each material, depending on the thickness withstands vapor diffusion. This air water vapor diffusion resistance ratio of the resistance “water vapor diffusion resistance coefficient” is. Μ = 1 if not completely free of water vapor, if not ever exceed = μ. (Eg aluminum) and is expressed. μ = 10,000 – 100,000 materials in the “vapor barrier” is called. Insulation materials When selecting particular need to consider that value.

Sweating (condensation)

The air on the surface of a building element, the result is transformed into the water vapor condenses into water. If the temperature of the air in contact with the surface, if the water vapor dew point temperature falls below the pond surface water particles occurs. For example; the inner surface of the window glass in winter like to be seen sweating. Of the structural element to prevent sweating is required to increase the heat transfer resistance.

Why and Where to condensation formed

insulation in the cold air duct line, capable of absorb water is and have taken measures against the vapor transmission or a sealed application have not been made, the number of times the resistance to water vapor diffusion, such as fibrous materials with very low [μ = 1.1 (water vapor diffusion can not resist at all)] through the use of insulation material, although not enter the surface condensation of water vapor condenses into water in the insulation material and the material becomes.

Condensation Results

Thermal insulation materials in the water causes corrosion in plumbing. A result of corrosion decay begins. See coating loss on the insulating material. This destroyed the system requires a renewal of this section.

Deformation of the condensation channel isolation results

Internal condensation

occurring in the inner side of the structural element is observed in the initial formation of water accumulation unnoticed. over time may dry deposition or surface water may cause corrosion. This accumulation of physical events (air movement, temperature difference, mechanical cleaning, etc.) Does not pose a hazard can be taken as a result.

Measures should be taken out if this does not occur. That prevents the sweating does not prevent internal condensation. Internal condensation should also be checked.

Conditions in which condensation and where Occurs

– Insulation will be condensation on the surface of the installation is not done.

Figure 1.2: If the insulation surface condensation will be made.

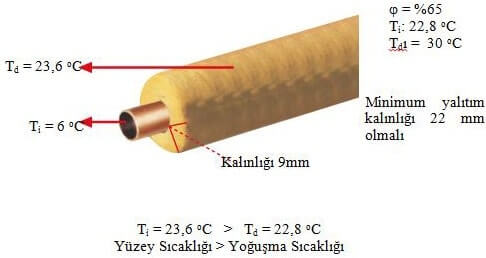

– If insufficient insulation made of condensation becomes the surface of the insulating material.

Figure 1.3: condensation on the surface would be done if the insulation is insufficient.

– The thickness of the insulating value of μ would be sufficient and the structure of the material at low condensation.

Figure 1.4: Thermal insulation is not made within the condensation on the surface would not be enough.

– Not enough condensation in materials with a high water vapor diffusion resistance coefficient.

Figure 1.5: If no condensation is done adequate insulation.