Wave energy is obtained either directly from surface waves or surface waves under pressure. The waves produced by winds blowing over the surface of the sea or ocean. The world’s wind will create permanent waves in many parts as a regular and continuous work. Sea and in a very large ocean wave energy. Wave energy machines produce energy directly from the surface motion of waves or wave pressure.

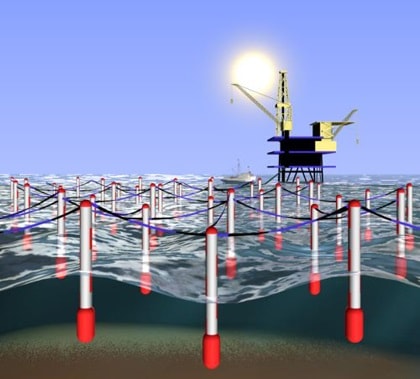

A variety of technologies have been designed to use wave energy. The practice tests are performed some of the most suitable design for commercial use. Wave energy technologies shore, the shore was designed to establish a little off and the open sea. the system will be set a little away from the sea is more than 40 meters deep in the water.

Although all wave energy technology is designed to be installed near the water surface or water surface, they interact, they vary according to the energy they turned the tide and wave energy they adapt. wave energy technologies are listed below the target of recent developments.

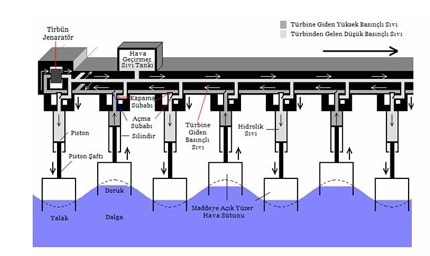

Terminating extends vertically in the direction of movement of the wave machine and reflect wave energy or catches. Although recent versions of these types of machines designed to be installed in close proximity to the sea, the beach is usually designed to be installed in or near the beach.Oscillating water column is another type of finisher machine. This machine is tucked above the bottom surface water enters a chamber with air. Water entering the wave motion up and down like a piston and is capable of moving air pushes turbine connected.

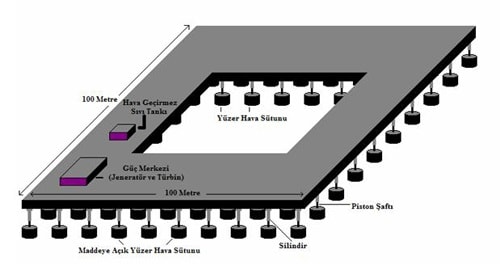

Point absorber wave surface acting as a structure with components connected to each other by the movement. Linked motion used to drive electromechanical or hydraulic energy converters.

Mitigating are oriented parallel to the direction of the waves long multi-part floating structures. During the height of the wave machine difference causes the bending and twisting of the point where the parts are connected to hydraulic pumps or other converters.

Out maker of machines are high surrounding reservoirs filled with water from the sea or by waves in excess of the average level of the ocean. after rising water gravity causes the retreat towards the sea surface. Sucked out the energy of the water is used to rotate the water turbine. The offshore vessels specifically designed store the energy of waves on the coast are slightly open. This floating platforms waves are produced by passing electricity through a turbine and enabling the return of internally sea.

Wave Energy Generation Systems

Wave energy conversion technologies along the shore, near-shore and shore can be divided into three main groups, namely those applied in remote areas. Wave height and frequency of the wave energy are essential elements to be obtained. Each wave height in order to obtain the desired energy is one of the major advantages of wave energy.

Shore (Shoreline) Applications

Shore applications, energy production fixed onshore structures or embedded therein are located.Maintenance and construction is easier compared to other applications and there is no need for deep-water connections or long underwater electricity cable. However, wave energy may be less due to less power can be obtained with a wave regime. The spread of such practices coastline geology, tides are limited by factors such as the level of protection and coastal structures.

• Oscillating Water Column (OWC-Oscillating water column)

water column in this system has an air column on it. It allows water from entering the bottom door. air passing through the narrow portions being compressed by the water moves turbine outlet. Wave to release the air inside retreated again this movement would ensure that the turbines. If water enters the room normally used in this system and the turbine blades of a turbine leaving the room will be turned in different directions. In this case, because it will reduce the energy production propeller stopped working.

However, when wells turbine used without any loss of time due to the special nature of this turbine rotation is always provided in one direction and allow for a more efficient energy production.

• Shrinking Channel System (tapered -TAPCH the chanel)

These systems have high walls 3-5 meters above the water level, feeding the reservoir was built on the edge of the cliff consists of a tapered channel. The narrowing of the channel causes an increase in the wave height and is discharged into the reservoir from rising waves channel wall. kinetic energy of the moving wave is stored in the water reservoir back to potential energy. It can be stored water turbines. Very few moving parts is the lower maintenance costs and a high reliability. energy can be stored until needed in this system. However, the system is not suitable for all coastal areas.

• Pendula

Pendular, is shaped like a rectangular box opening to the sea side. This opening is hinged lid on a pendulum. Cover wave is moving back and forth with the movement. This movement is used for the operation of the generator and the hydraulic pump.

Close to the coast (Near Shore) Applications

It is carried out in a water depth of 10-25 meters. These applications include the following.

• Osprey

Waveg Osprey developed by the inclusion of the power of the 1.5 MW wind turbine has been increased to 2 MW. It is on quite a lot of work done for commercial representation of the system and especially in order to reduce the cost of building work is continuing.

• WOśP 3500

WOśP (Wind and Ocean Energy Release) inshore wave and wind energy combined state of the station. The added production capacity of 1.5 MW wind raises plant capacity of 3.5 MW.

Offshore (Offshore) Applications

devices are used in water deeper than 40 meters away from the shore applied. In such systems there is a need for long electrical cables.

• McCabe Wave Pump (McCabe Wave Pump)

This device is hinged to each other, and sorted on a regular basis 3 rectangular steel moving linked (4 m wide) pontoon. The increase of mass with the addition of an extra pontoon center of inertia is provided. Energy is provided from the movement in the center between the barge and other pontoons mounted hydraulic pump through the hinge point. Example device Kilbaha 40 meters in length, was founded in County Clare and Ireland.

• OPT Wave Energy Converter (WEC)

2-5 meters in diameter covered the base of the open sea contains a cylindrical structure. hydraulic pump is disposed between the floating steel structure with swimmers in the top of the structure.Generating electricity from the motion of the structure according to the swimmers. This system has been tested on a large scale in the eastern Atlantic and the first commercial structures are to be established in Australia and the Pacific.

• Pelamis:

This structure is located partly in the water, composed of cylindrical sections linked by hinged point an articulated structure. Wave moves with joints and hydraulic pumps, electric generators running this movement. Today, 375 kW, 130 meters long and 3.5 meters wide efforts to develop a system of continuing.

Archimedes Wave Swing

This system is 10-20 meters diameter, contains air-filled swimmer. Waves passing through the system, will increase the pressure of the air inside the swimmer or down. Thus, according to the swimmer’s rise and fall movement causes the ground to energy production.