Solid fuel Boiler incineration, sports, fighting, cleanup operations in conjunction with the boiler water temperature, circulation pump, air valve, the chimney damper setting ashtray care: cleaning of the smoke pipes and describes in detail such things.

Solid Fuel Boiler Burning

Igniting the fuel

Solid fuel boiler water level in the system before burning the hydrometer (hot water system) or the gauge (steam system) checked and missing is completed. maximum 50-60 mm coal to be taken in January. (Fist size) should be. Great coals must surely break.

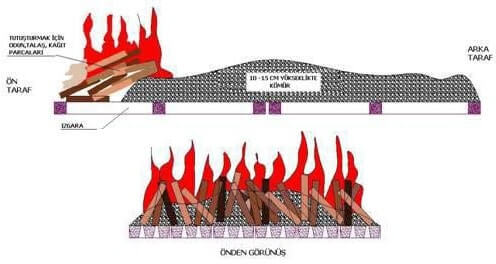

Boiler coal loading door properly on the opening, coal series 10-15 cm thick. In front of the grid (a little), except the place to be wood, coal has been laying the ground patterns remain (especially in corners) is checked. Front-placed wood or chips. Coal or wood chips placed on the front side;paper, such as oily rags ignited by placing parts. no way to ignite flammable as gasoline, explosives used. Coal lid is closed. Ash opened the door of the natural draft of combustion of the coal supplied to the end.

Win A Fuel Feed

When the fire spread over the entire grilling surface, the boiler capacity over the fire 1/3 “ü supplement is made up of coal. Ash left open burning half cover is provided. Incomplete combustion ash established the lid is closed.

Figure 4.1: boiler ignited the

Win Air Setting Needs To Be Done

Ash covers are provided half way open burning. Incomplete combustion ash established the lid is closed.

Boiler Water Temperature Control Make

Boiler water temperature (thermometer on the boiler) must be set according to the temperature of the outside air.

Run the circulation pump

Automatic control of the boiler water temperature in the model 30 – 40 ° C “to exit the pump operates automatically and is engaged. In other embodiments, the boiler temperature range 30 – 40 ° C “when eat out recirculation pump bypass valve closing run.

Incineration Boiler

By looking at the boiler furnace peephole combustion is good (orange flame out). The grill coal becomes always present coal embers, flashing the grid on the right half is collected throughout the grid. To the left side of the grid are laid new coal. Thus, the right half of the grid with a cushioning method, a left half continue to burn coal series booklets.

Figure 4.2: Win the construction of pillows

When it opened in January ingoing cold weather, because the break-cooling furnace combustion and therefore caused the loss of coal, coal shoveling, fogging, slag removal must be done very fast closure of the pit cover. When the boiler bottom ash from the grill lid understood as the light does not appear when the bayonets and shoot ash sliding surfaces is reduced under the bayonets grill grate.Pressing lightly on the bottom side bayonet slag are removed on fire.

Bayonet on fire after the end of the process is taken with the hook without disturbing the position of firing the slag (Slag never be taken with a squeegee) .If the slag is taken out after a while full of unburned left on fire. After tapping Bayonet taken out with rake falling ash in the bottom of the grill.This process is done carefully fire with full efficiency combustion, enables the prevention of air pollution from coal and economizing. Fire is the most important condition for the good side; need that air is getting full. For this reason should not neglect the bayonet tapping and exerting maximum effort not to keep the ash layer on the grid. Grill surface should be covered with a layer of fire all openings should not. If the air can not penetrate if the openings in the grid surface coal would fall easily from the opening and coal does not burn well. not to miss the coal extraction time should be noted in particular. If coal has lost his temper in the gas contained in the newly thrown out of the chimney from burning coal cause.

The boiler water temperature (thermometer on the boiler) should be adjusted according to the outside temperature. January’s cover shoot coal throwing cold air to pass through the fire should be closed and subsequently prevented as much as possible. Ash air cover should be adjusted according to fire speed. Circulation pump runs, boiler water temperature will drop. The boiler water temperature to leave until the beginning of the boiler according to the outside temperature

Next, check the combustion hours. Arrange fire after hitting the right and left of the bayonet at this time in January and the other half pillow shaped charcoal grill, you must leave the other half of the grill flame. New discarded coal unemployed it is possible to incinerated. Continue to suit daily with herringbone method.

Solid Fuel Boiler Sleep

Burning Fuel Feeding

It becomes available when the charcoal grill on charcoal embers blinking, collected along the grid on the right half of the grid. series of new coal ash to the left side of the grid. The coal will be gradually laid hold after a while. Thus cushioning method with a right half of the grating is continued coal burning laying a left half.

Fuel In The Parent Tables Covered In Ash

We know that to be burning oxygenated combustion air is required. Intense burning coal, burning on contact with air to slow down on need to reduce. Ash on the burning of coal for it with logged off.Fesi. This process slows down the movement of people, especially during the night.

Closing of the boiler cover

Fire and ashes should be considered airtight lid when the lid is closed the air. If air leaks İayet remedies for their removal should be sought as soon as possible. Boiler flue and chimney cap with contacts of the outlet pipe should be such as to prevent leakage of air. If air leaks in them must also be resolved.

Reductions of the flue damper

The rear dampers are replaced in the smoke box chimney outlet pipe. It provides maximum efficiency by allowing an exact setting of the required chimney for the boiler combustion and allows you to run at lower capacity. Win up to leave lying in front of the setting arm movement boiler flue gases resulting from combustion boilers moved in the narrowed opening. Thus, burning is slower.Burning gas instead of burning it out and would not come under control for new combustion gas.

Solid Fuel Boiler Fighting

Soaked In The Parent Tables Covered With Ash Fuel

Completing the burn earned under normal conditions, when it is necessary or in any danger, deflation, soaked onto the fuel ash. Thus the air contact with the coal burning boiler is disconnected.Air cut contact with coal.

Air Valve and Ashtray Cover Closure

Ashtray, solid fuel boilers combustion occurring as a result of the ash is collected. Also located in the front of the air required for combustion is supplied cover Cap. This is required for combustion air closing the lid would be blocked and win will have deflation. Air valve combustion air is an other details and air setting is done here. The cover is completely closed combustion air nor solid fuel boiler slaked.

Solid Fuel Boiler Cleaning

Brush Types

Boiler cleaning of flame tubes within is important. This cleaning is done with brushes produced in a variety of ways. Brush types:

– Plastic gasket head brush

– Screw the cylindrical steel wire brush titled, demountable

– Screw the tele-wrapped wire brush

– Normal straight hand brush

– Round hand brush

Cleaning The Grid

On the grid is coal burned. With the help of g. ashes on the grid. In this respect, it should be done once a week.

Cleaning The Stove

Fuel is burned. Stuck in the ceiling and smoke contaminants from the hearth, cleaned with the brush.Annual maintenance should be cleaned.

Clearing The Smoke Box Front

It is in front of the boiler. Take one pipe from angry, slamming the CAP here are second shot reaches the back tube. Dumandaki during the multiplication of unburned materials, creates the premises here. These institutions are cleared.

Clearing The Smoke Pipes

When passing through the flame and smoke pass, warms the water pipe outside, too. Cleared with the appropriate diameter wire brush. Monthly care should be cleaned.

Rear Smoke Box Cleaning

Smoke channels institution that regimen of cleaning the brush is collected in the rear smoke box.Accumulating bodies are cleaned by opening the door.

2 Comments

Solid boiler installation is very important subject. So that it need to made by expert. Thank.

Thank you for that article, regards