Cooling tower pump, float and discusses factors that should be considered during assembly and installation of equipment.

Floater Structure

Floater, automatic water filling device. Water tank, water tank used for or in areas near water, such as diminishing water supply from the reservoir automatically complete. Floater market a name other widely used in the floating gate valve.

Floater, and a valve working with the buoyancy of water. The water level in the tank is mounted will be little or no water level or float ball. Thus, the arm is attached to the handle of the ball and will allow the water tank will not pressure seal inside the valve inlet. Thus, the tank will start to fill up water.When the water level reaches the maximum level float switch is set, the buoyancy of the water will remove floating ball. Floating balls to lift the handle up and applying pressure to the gasket in the valve arm will cut off the entrance to the water. Thus, the lower and the upper level of the water inside the tank will be automatically adjusted with the help of float.

Cooling Tower Flat Practice

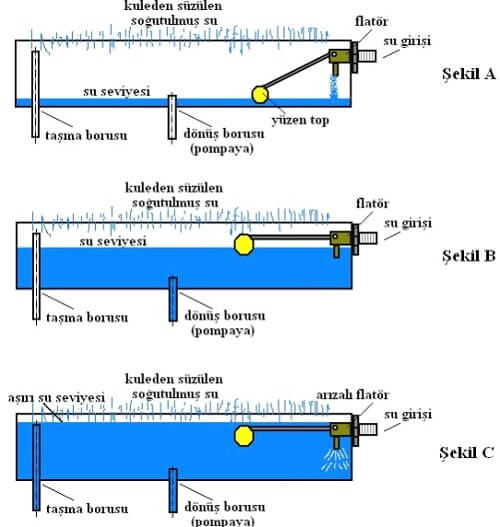

The following figure shows the float of the water tower we can see more clearly the application.Figures a water level in the water tank of the water cooling tower is relatively low. There are ball float down and thus water inlet is open. In this case it starts refilling the water tank. In Figure B it has reached the maximum water level of the tank float is set in advance. The ball goes up the float arm lifting force and the water pressure is applied to the arm and stops the water inlet side of the valve seal.

Figure C is flat gasket rupture or blockage of the results has failed. This is the case loses its sealing function continues to water ingress. The water level in the tank has exceeded the maximum limit. In this case, going to prevent damage to the structure and other elements of the rising water task falls to the overflow pipe. Water through the pipe, the structure of the drainage channels may flow without damaging the environment.

Floater, cooling towers should be installed as specified in the installation instructions for the water tank. Mounting height of the tank must be taken to be above the maximum height. Tank plate, the threaded portion of the float is drilled by the manufacturer so that the situation now complete. Flat hair is compressed when the tank through the lock nut assembly work here is completed. which is to be perforated by the float height of the manufacturer where it can be assembled by the following method. While full float arm is essentially parallel to the valves and close the valve does not allow water passage. If the desired water level in the water tank so that the float is mounted able to operate in a healthy manner. Float structure of the water float connection portion with the pipe after installation is complete withdrawal from the network is completed. float float entry to malfunction from time to time may require adjustment to, or could, it would be appropriate to put a ball valve.

Cooling Tower Pumps Installations

Pump energy received from external sources, is defined as a location somewhere transferring said liquid transporting machine. The task of the pump in water cooling towers, the water cooling tower, the water tank tower base to provide a water-cooled condenser to be resubmitted. Thus, condensate and becomes a continuous circulation of the water tower.

The pump is connected to a water cooling tower in water circuit, the system must contain the following elements to work properly and regularly:

– Global Cutting Valves: Water filter, float, ordinary elements like towers and pumps are used to cut and extraordinary maintenance in case of circuit waters.

– Water Filter: Located on the pump suction tube. This filter can be controlled and removable property. Water tank and the possible residue that may be inside the tube (dust, sawdust) will prevent it entering the rotary pump assembly and the condenser water circuit.

– Circulation pump: ensures the circulation of water in the system. The power of the pump, the horizontal length and height difference between the cooling towers and condenser is determined by the manufacturer considering. All parts in contact with the water pump stainless steel. The pump on the electrical panel must be protected by a thermal switch is mounted.

– Water Tank: This is where storage of chilled water in cooling towers. Stainless steel material is made watertight. water coming from the condenser to the tower, is slightly reduced due to the evaporation and loss of water in the system becomes. Therefore, diminishing automatic and manual water in the tank to complete the water filling device should be found.

– Water filling tap: The manual types. In cases where the system operation of the automatic water filling device used for the completion of the diminishing water.

– Floater: The automatic water filling device. Another name for the floating gate valve. diminishing water in the water tank, automatically completes the clean water supply.

– Overflow Pipe: Floater automatically cut the water will rise if not an excessive amount of water in the water tank. This water structure tachypnea and overflow pipe from the tank to the desired maximum water level in the tank to prevent any damage to other components are placed. more rising water in the tank is removed from the tower through this tube so harmless and thrown into the drainage channel.

– Drain piping: air condensation in the cooling towers and pipes laid for water splashes and water seepage due to the drain pan or removed without damaging the structure of the water collected in the channel.

– Bypass Valve: In the event of circuit cooling towers, condensers used for short- circuiting of the valve of cooling water.

– Vibration absorber pipes: Through vibration generated in the pump to the other elements of the installation and flexible to avoid contact structure can be bent easily, the pipe made of rubber or steel.

The above shape water cooling tower water system is a simple example. In very different ways, a number of additional elements that use different systems can be installed. Where to go through this installation, technical specifications of the pipe diameter and element manufacturer’s instructions shown on the air conditioning project considering. Our task in the light of these elements make the installation of our systems and to laying the pipe network information. If the building’s air conditioning or a new type of project or the construction of a water cooling tower to be followed exactly mounted if the manufacturer’s instructions.

In fixing plumbing coolers it should be noted the following points:

– The location of the elements should be determined according to the project, it should be marked place to pass the plumbing.

– Suitability of the mounting location of the elements to be checked.

– Clean water pipes in the building, the location of the sewage pipes and drainage channels should be examined connection status should be determined.

– Properties of building components will pass the pipe must be known to damage the structure of the carrier system plumbing should be avoided.

– Water tower and central air conditioning plant location should be determined relative to each other, and going to be determined by the shortest and most convenient route to the return pipe.

– Sleeves to be suitable for elements such as floor and wall to go through the pipes should be prepared and put into place.

– The circulation pump should be put in place, if necessary, should be fixed to the floor with suitable mounting elements.

– Floater must be installed instead of the overflow pipe, flat, fixed installations, such as drainage pipe and nozzle tip to be made.

– Diameter pipe envisaged in the project, with the appropriate joining techniques to the type of pipe, valves, additional materials and using all laying pipe network should be completed.

– During the pipe-laying process, it should be noted that the console should be placed at appropriate intervals and handcuffs.

– Laying of pipes 3. Activities involving “issues to be considered in laying pipes” to the matters discussed under the heading should be followed.

– It must be tested sealing of the installation and the operation control system must be made.