Biogas organic-based waste / residues of anaerobic (anaerobic) fermentation of the resulting colorless – odorless, colorless, tasteless, depending on the composition of organic matter in a bright blue flame burning and ound about; 40-70% methane, 30-60% carbon dioxide, nitrogen and hydrogen is a gas mixture present in very small amounts with 0-3% hydrogen sulfide.

Calorific Value of Biogas

1 m3 amount of heat provided by the biogas 4700-5700 kcal / m3. 1 m3 of biyogas; 0.62 liters of kerosene, charcoal 1.46 kg, 3.47 kg of wood, 0.43 kg of butane gas, is equivalent to 12.3 kg of dung and 4.70 kWh of electricity. 1 m3 of biyogas to 0.66 liters of diesel, 0.75 liters of petrol and 0.25 m3 of propane are the equivalent amount of fuel.

Biogas Production Process

Organic waste / raw materials now used in biogas production

Animal Waste

Cattle, horses, sheep, feces of animals such as chickens, slaughterhouse wastes and wastes generated during the processing of animal products are used in the proposed biyogas plant, especially in rural areas.

Vegetable Waste

Finely chopped straw, stubble and corn residues, sugar beet leaves and grass unhandled parts of plants, such as crop residues during the processing of the resulting residues.

During the operation of biyogas plants that use of plant process control it is of utmost importance now.Therefore it not recommended obtaining biogas from plant residues in the countryside.

Organic Content Urban and Industrial Wastes

Sewage and sludge, paper industry and food industry wastes, the concentration of dissolved organic material is used in the production of high industrial and domestic waste water and biyogas. These wastes are mainly municipalities and large industrial facilities by using high-tech biogas plant is the production of waste are used in the center.

Quantity of Methane in biogas and biogas yields can be obtained from various source

Animal weight per day can be produced in some quantity of fertilizer and Annual Age

• 5-6% of the live weight of cattle aged manure kg / day

• Sheep and Goat 4-5’s% of the live weight kg wet manure / day

• The 3-4’s% of the live weight kg of chicken manure-age / day

Matters to be Considered in the production of biogas

• The fermentor (production-digester tank) must not be found oxygen,

• Antibiotics should be taken to produce animal waste tank

• detergent organic waste should be taken into production tanks,

• Creating new bacteria in the environment and should have sufficient amounts of nitrogen for growth,

• acidity in the production tanks 7.0 – should be between 7.6,

• substrate for methane bacteria (S) organic acid concentration in the acetic acid 500-1500 mg / liter should be about,

• The fermentor temperature should be kept constant at 35 ° C or 56 ° C,

• not enter into the production of light and medium tanks should be dark,

• 50% minimum in the production tanks, must be optimal 90% water,

• enough to feed the media methane bacteria must be broken-ground organic matter.

Design and Considerations in the Design Parameters of Biogas Plants

Biogas plants are constructed using different technologies, according to the intended purpose.Classified as capacity of biogas plants are as follows:

• Family type: 6 to 12 m3

• Farm type: 50 -100 -150- m3

• village type: 100- 200 m3

• Industrial-scale facilities: 1000 – 10,000 m3 capacity

Family type biogas plants are mainly used in close proximity to the very widespread use in China.Family type biogas plants by other plants other than the majority of the biogas formed media (fermentor) heating is required for optimum biogas production. Be around 35 ° C ambient temperature in the biogas production is requested. Biogas plants can be used for temperature control in order to provide the most practical and widely used solar power system, built into the plant benefits from hot water coils.

Systems used in biogas production

a) Batch (Batch) Fermentation

Facility fermenters (manufacturing tank) animal and / or vegetable is filled with waste and retention – holding formation of the waiting period until biogas is completed. wait time depending on the organic material used, and the system temperature ranges. After this time the plant fermentor (reactor) is discharged and recharged completely.

b) Fed – Batch Fermentation

Here is filled with a certain proportion of organic matter is initially fermented and is completed with the remaining volume was divided by the daily amount of fermentation time. After a certain period of fermentation fermenter is completely emptied and refilled.

c) Continuous Fermentation

When this fermentation gas output format from the fermentor began feeding is done on a daily basis.until the mixture transferred to the system degassed taken out of the sediment system. Organic matter in the fermentor are given a certain amount every day, on hold until the retention period is taken from the fermentor and fermented material on a daily basis at the same rate. Thus, continuous production of biogas are provided with daily feed.

Matters to be Considered in Facility Design

Suitable raw material amount, type and characteristics of the raw materials, heating needs, blending needs, the kind of the material and equipment used, the choice of where to set up the plant for the construction and installation of insulation, heating and operating conditions of the plant, the storage of biyogas and distribution, to transport the biyogas to store the bio leaving the facility , transport and distribution of agricultural land and to determine the use of biyogas vehicles should be taking into consideration.

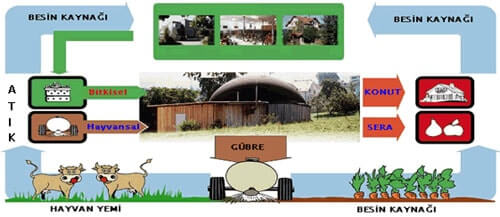

Benefits of Biogas Production

Animal and vegetable organic waste / residual materials often are either directly as fertilizer or be burned into the agricultural soil. The use of especially incineration of such waste heat production is more widespread. In this way such temperature can not be produced with desired properties after heat generation is not possible to use the waste as fertilizer.

• Biogas technology of organic origin wastes / residues of both to obtain energy from waste matter and give an opportunity to acquire the land.

• Cheap – environmentally friendly source of energy and fertilizer.

• It provides waste recycling.

• weed seeds can be found in biyogas production as a result of manure loses its germination property.

• The smell of manure in biyogas production results are not substantially be felt.

• provide human health resulting from animal manure and groundwater in the event of the loss largely to the factors threatening diseases.

• do not waste even after biyogas production has become much more valuable organic fertilizer.

Uses of biogas and Peripherals

Use of Biogas heating

in biogas combustion characteristic composition comes from methane gas. Gasification occurs when air mixed with 1/7 the rate of complete combustion. Heating order gas fuel-fired furnaces and ovens can be used from the water heater and water heater used, running on biyogas. Biogas, liquefied by pressure adjustment of the nozzle diameter gas and oil furnaces can be used easily. a flue system of biogas stoves when used on-site to prevent the release of hydrogen sulfide gas combustion is necessary. Therefore, heating is preferred for a healthier warming.

Using Biogas Energy Purposes

Biogas can be used in both direct combustion as well as lighting converted into electrical energy. by liquefied petroleum gas in the use of biyogas is utilized in direct lighting working lamp. asbestos liner and a bell jar is used to increase the flames in this system. The heat of the flames giving back as glass lantern light fix is to ensure that more.

Use of Biogas Engine

Biogas gasoline powered engines without any additives or agents can either be used to give the content of methane gas can be used. When used in diesel engines, a specific amount (18-20%) of diesel to be mixed with.

Byproducts Evaluation Facilities

Biogas production results are obtained in liquid form fermented organic fertilizer. The resulting liquid fertilizers as a field applicable, can be granulated and / or in-ground pool concrete can be left to natural drying. The main advantage of organic manure fermentation results obtained as a result of anaerobic fermentation of pathogenic microorganisms is that there is a large part. This feature is about 10% of the organic fertilizer to be used ensures more efficient.

World Biogas Production

80% of the world 10% for plants in China, India, Nepal and Thailand are. If Europe is to look at the number of animals derived by the biyogas plant and the fertilizer at this point, Germany is the country with the highest production with 2,200 plants. These countries are followed by Italy with 70 plants.construction of biogas plants in Germany has increased since 1993, and increased again from 139 up to 2,200 plant facility until today in the same year.

Source: Directorate General of Renewable Energy